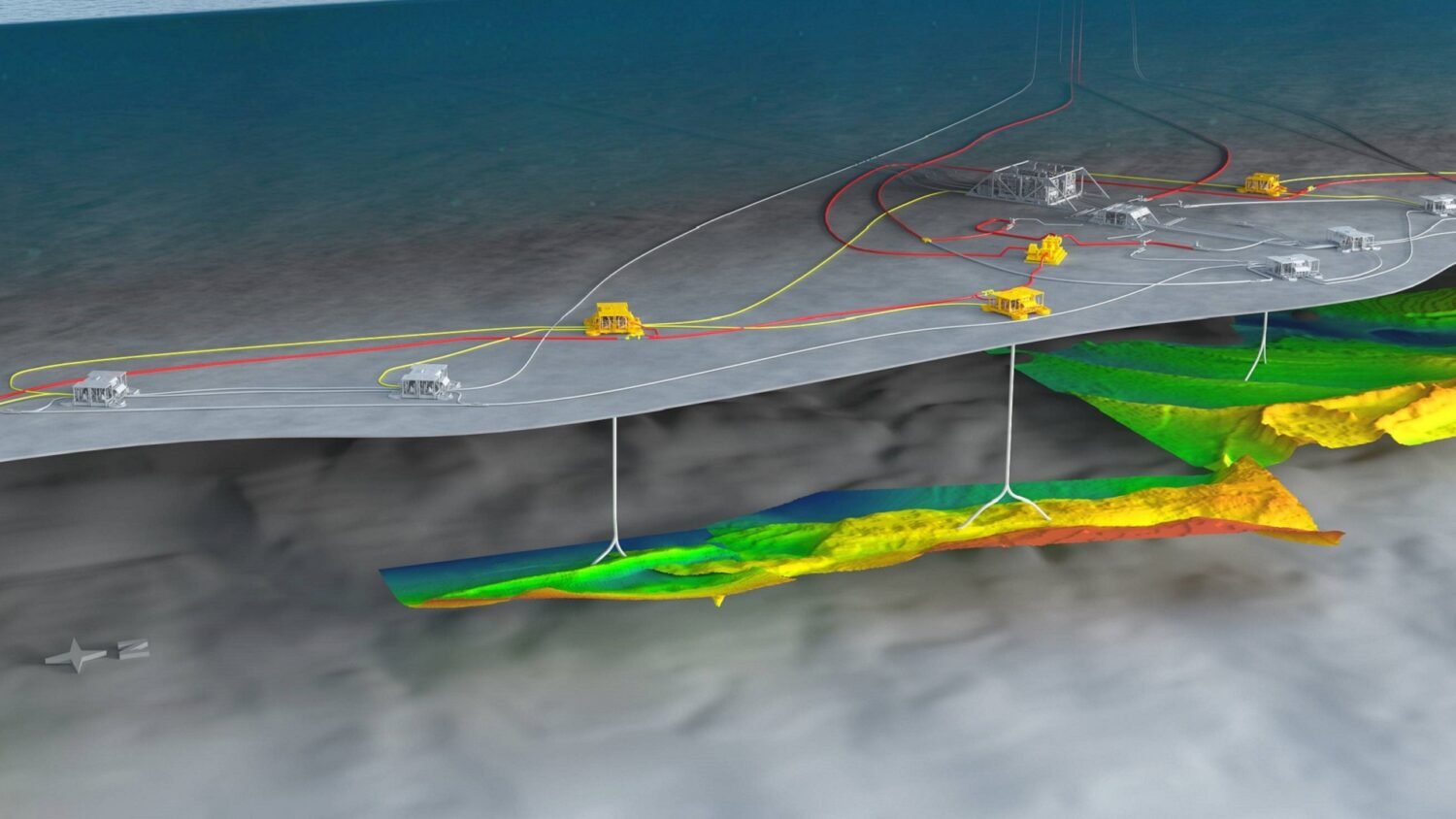

Further Design of Subsea Pipelines

Advanced Pipeline Design

Interactive Learning

Industry insights

Networking Opportunities

Networking opportunities

Engage in hands-on activities and interactive exercises, helping you become confident in subsea system architecture.

Jeenius

A Problem-Based Learning Journey

Module Highlights

Day 1 - Soil Interaction, Buckle Arrestors, and Corrosion Mitigation in Pipeline Design

Day 2 – Structural Stability and Design: Exploring Lateral and Upheaval Buckling, Virtual Anchors, and Strain-Based Design

Day 3 – Navigating Structural Challenges: Fatigue, Expansion, Walking, and Anchoring

Day 4 – Ensuring Pipeline Integrity: HIPPS Configuration and Pipeline Protection Strategies

Who should attend?

Navigating the Course: Daily Breakdown

Pipe soil interaction

-

Soil types and properties

-

Pipeline embedment

-

Axial pipe-soil interaction

-

Lateral resistance

-

Buried pipeline upheaval resistance

Hydrostatic collapse

-

Need for buckle arrestors

-

Buckle arrestors

-

Worked example

Corrosion

-

Corrosion mechanisms

-

Corrosion control

-

Corrosion rates

-

Case studies

Lateral buckling

-

Virtual anchor spacing

-

Design process

-

Out-of-straightness surveys

-

Buckle mitigation

Upheaval buckling

-

Upheaval buckling mechanism

-

Upheaval buckling analysis

-

Worked example

Strain-based design

-

What is strain-based design?

-

Loading

-

Low strain requirements

-

Moderate strain requirements

-

High strain requirements

Fatigue

-

Principles of fatigue

-

Fatigue loadings

-

Design for fatigue

-

Worked example

-

Case studies

Expansion, walking and anchoring

- End expansion

- Pipeline walking

- Walking modes

- Pressure effects

- Walking and lateral buckling

- Anchoring

- Other prevention and mitigating measures

- Case study

HIPPS

-

Configuration and components

-

Design applications

Pipeline protection

-

Hazards

-

Pipeline loads

-

Pipeline load capacity

-

Risk and safety analysis

-

Pipeline coatings

-

Rock dump

-

Trenching for impact protection

-

Protection structures

-

‘Soft’ protection options

Learning Outcomes

- Summarise the design approaches for HP, HT and high corrosion

- Design for collapse and buckle propagation resistance

- Explain how to calculate corrosion rates and determine the associated mechanisms and methods

- Describe the evaluation of different levels of strain and their design requirements

- Investigate the causes of fatigue and how to calculate acceptability

- Explain how to assess and mitigate pipeline walking

- Predict potential hazards and recommend pipeline protection method

Meet Your Expert Tutors

Dem Demetriou

BEng (Hons), MSc, DIC, CEng, FIMarEst, MBA FCMI

With a rich professional journey spanning over two decades, Dem has established himself as a specialist in project management, facilities engineering, and strategic general management. His expertise encompasses Front-End Engineering Design (FEED), detailed and conceptual design, procurement, topsides, and construction. This extensive experience makes him a treasure trove of knowledge and practical insights, particularly in the dynamic field of subsea engineering.

In his teaching role, Dem brings this wealth of experience to the classroom. His courses are a blend of theoretical knowledge backed by real-world application, offering students a comprehensive understanding of the complexities involved in subsea engineering projects.

Martin East

CEng, MIMechE, NRA

Martin, a Chartered Mechanical Engineer since 1988, is a cornerstone of Jee's technical expertise, particularly in the realm of finite element analysis (FEA). His profound mastery of the Abaqus non-linear FEA software sets him apart as a leader in his field. Joining Jee in 1996, Martin has been instrumental in steering consultancy projects and advanced analysis, showcasing his deep understanding and practical application of engineering principles.

Martin's role extends beyond his technical contributions. As one of Jee's most knowledgeable and experienced tutors, he has been at the forefront of delivering many of Jee's training courses. His teaching style is characterised by clarity, depth, and a strong connection to real-world engineering challenges. Martin excels in breaking down complex analytical concepts into understandable segments, making them accessible and engaging for students of all levels. His commitment to education is evident in the way he nurtures and inspires future engineering talent, making him a valuable asset not only to Jee but to the entire engineering community.

Start Dates

| Location | Start Date | End Date | Number of Days | Timings |

|---|---|---|---|---|

Virtual (via MS Teams) |

17th June 2024 |

20th June 2024 |

4 |

09:00 to 16:30 (with regular breaks) |

Your Course Fee

COURSE FEE

£2,495

-

Live Classes: Dive into live, interactive sessions focusing on real-time learning and discussions with peers and industry experts.

-

Access to Jeenius Platform: Unlock a realm of additional resources, peer forums, and expert interactions extending your learning beyond the classroom.

-

Industry Expert Interaction: Network and learn from seasoned industry professionals throughout the course, discussing real-world challenges and solutions.

Find Out more