About the Course

The Subsea Systems and Hardware course is an extensive programme tailored for professionals in the oil and gas industry, focusing on the intricate design, operation, and maintenance of subsea systems. This four-day course provides a comprehensive understanding of subsea architecture, drilling and completion, control systems, and subsea processing, essential for maintaining the integrity and efficiency of subsea infrastructures.

The course begins with an introduction to subsea systems, emphasising the design considerations and host facilities crucial for successful subsea operations. Delegates will explore the fundamental aspects of subsea system architecture, including field layout, system components, and flow assurance. The initial sessions provide a broad overview of how subsea systems integrate with host facilities, ensuring seamless operations from the seabed to the surface.

Drilling and completion of subsea wells form a core part of the curriculum. Participants will gain insights into the hardware and operational sequences involved in subsea drilling, from well planning to the deployment of subsea trees. The course covers the selection and installation of subsea trees, focusing on their functions and the critical role they play in controlling the flow of hydrocarbons. Detailed discussions on wellhead systems, completion designs, and intervention techniques equip delegates with the knowledge needed to manage well integrity throughout the lifecycle of the well.

Subsea control systems are another key focus area. The course delves into the various types of control systems, their components, and the technological advancements driving efficiency and reliability. Participants will learn about subsea control modules, umbilicals, and distribution systems, understanding how these elements work together to monitor and manage subsea operations. The sessions cover the installation, testing, and commissioning of control systems, providing practical insights into ensuring operational readiness.

The course also addresses the complexities of subsea processing, highlighting technologies such as subsea separators, pumps, and compressors. Delegates will explore the benefits and challenges of subsea processing, including the reduction of topside processing requirements and the extension of field life. Advanced subsea processing technologies, such as multiphase flowmeters and subsea boosting systems, are discussed in detail, offering participants a deep dive into the latest innovations in subsea technology.

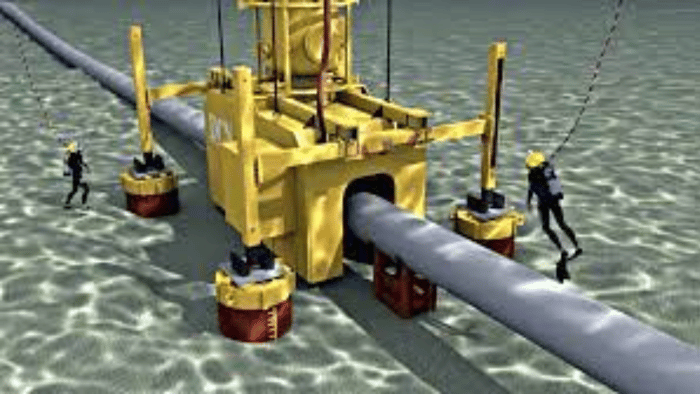

Inspection, repair, and maintenance (IRM) are critical components of subsea operations, and this course provides thorough training in these areas. Delegates will learn about the tools and techniques used in subsea inspection, including remotely operated vehicles (ROVs) and autonomous underwater vehicles (AUVs). The course covers non-destructive testing methods, corrosion monitoring, and integrity assessments, ensuring participants are well-versed in identifying and mitigating potential risks. Repair strategies, including clamp installations and pipeline repairs, are also discussed, providing practical solutions for maintaining subsea infrastructure.

The practical application of theoretical knowledge is a cornerstone of this course. Through detailed case studies and real-world scenarios, delegates will gain insights into successful subsea operations and the challenges faced in the field. These case studies illustrate best practices in subsea system design, installation, and maintenance, enabling participants to apply learned concepts to their professional roles effectively.

Collaboration and knowledge sharing are encouraged throughout the course, fostering a learning environment where participants can exchange experiences and solutions. This approach not only enhances the learning experience but also helps build a network of professionals equipped to handle the complexities of subsea systems.

By the end of the course, delegates will have a comprehensive understanding of subsea systems and hardware, equipped with the skills to ensure the operational efficiency and reliability of subsea infrastructures. This training is essential for professionals involved in subsea operations, providing them with the knowledge and tools to manage subsea projects successfully and contribute to the advancement of the oil and gas industry.

Who's it for

The Subsea Systems and Hardware course is tailored for professionals involved in the design, installation, and maintenance of subsea systems. This includes:

-

Project engineers managing subsea projects from conception to completion.

-

Installation engineers overseeing the installation and commissioning of subsea equipment.

-

Maintenance personnel responsible for the upkeep and operational integrity of subsea systems.

-

Technical team leaders and managers leading teams in subsea operations and project management.

This course is designed to enhance the professional development of individuals dedicated to advancing their expertise in subsea systems.

Learning Objectives

-

Identify key drivers influencing subsea system design and subsea field layout.

-

Understand the design and functionality of subsea equipment and their interfaces.

-

Recognise the pros and cons of equipment type selection for different scenarios.

-

Explain the installation and commissioning processes of subsea equipment.

-

Identify vulnerabilities of subsea systems and measures required for high integrity and reliability.

Course Content

-

Day One

Introduction to subsea

-

Key drivers for going subsea

-

Main elements of a subsea system

Subsea system architecture and design

-

Subsea system design considerations

-

Host facilities and export route

-

Subsea flowlines and risers

-

Tie-back distance

-

Enhanced recovery

-

Flow assurance and chemical injection

-

Subsea pigging

-

Water depth issues

-

IMR strategy

-

Reliability and redundancy

-

Template versus cluster configuration

-

Daisy chain configuration

-

Hybrid configuration

-

Satellite configuration

-

Subsea to beach

-

-

Day Two

Drilling a subsea well

-

Drill rig types and operation

-

Drilling sequence

-

Drilling hardware including subsea wellhead system, BOP and drilling riser

Completion of a subsea well

-

Well logging and testing

-

Completion sequence and hardware

-

Tubing and tubing hangers

-

Down-hole safety valve

-

Gas lift valves

-

Down-hole chemical injection

-

Down-hole sensors

-

Intelligent completions

-

Installing subsea tree and tree cap

Subsea trees

-

Dual-bore vertical tree

-

Horizontal tree

-

Mono-bore vertical tree

-

Tree selection

-

Valve functions

-

Instrumentation

-

Retrievable components

-

-

Day Three

Subsea Controls

-

Control system types

-

Topsides controls equipment

-

Subsea controls equipment

-

Control fluids

-

Fail safe shutdown

-

Umbilical systems

-

Flying leads (EHC)

-

Subsea HIPPS

Jumpers and connectors

-

Design considerations

-

Metrology and installation methods

-

Rigid spoolpieces

-

Flexible jumpers

-

Mechanical connections

Design of subsea structures

-

Manifold and template design

-

SSIV structures

-

ILTs, PLETs, PLEMs

-

Manifold foundations

-

Piping design

-

Manifold structural frame

-

Fishing protection

-

Coating and cathodic protection

-

Subsea valve types and function

-

Fabrication and testing

-

-

Day Four

Subsea processing

-

Subsea multiphase flowmeters

-

Subsea pumps and compressors

-

Subsea separation and water reinjection

-

Future technology

Installation and commissioning

-

Installation issues

-

Installation methods

-

At the seabed

-

Installation videos

-

Commissioning

-

Well hook-up and commissioning

-

Well put on production and start-up

Subsea IRM

-

Subsea vulnerabilities

-

Diving

-

ROV types and tools

-

ROV operations

-

AUVs

-

Subsea inspection and repair techniques

-

Integrity testing and workover of subsea wells

-

Learning Outcomes

Upon completion of this course, participants will be able to:

-

A comprehensive understanding of subsea system architecture and components.

-

The ability to design and implement effective subsea control and processing systems.

-

Practical knowledge of subsea inspection, repair, and maintenance techniques.

-

The skills to conduct thorough risk assessments and develop mitigation strategies.

-

Enhanced problem-solving capabilities through real-world case studies and scenarios.

These outcomes prepare delegates to effectively address the challenges in subsea system management, ensuring they can contribute significantly to their organisations and the industry.

-

Class Materials

- Case studies that explore real-world subsea engineering challenges and their solutions.

- A comprehensive course manual detailing all essential topics and technical data.

- Detailed notes from the tutor, Russell Thornton, offering additional insights and expertise.

- A collection of references and practical worked examples to deepen understanding and application of the material.

-

Jeenius

Participants in the Subsea Systems and Hardware course gain access to Jeenius, a cutting-edge learning platform that offers comprehensive support tools. This platform includes all course notes, recordings of the sessions for later review, and the opportunity for one-on-one support with the tutor. Additionally, Jeenius provides access to the latest insights in subsea engineering, enhancing the learning experience with up-to-date industry knowledge.

-

In-Company Delivery

For in-company delivery options and content customisation to meet your specific needs, please don't hesitate to reach out to us.

Book one of our in-company courses, tailored to your team.

Your Tutor

Russell Thornton

BSc Eng

LEAD TUTOR

Testimonials

"As expected Jee have provided us with a very good training course covering Subsea Systems from head to toe. It was a very good wrap-up of all what is related to Subsea Systems explaining a lot of what we do experience in our companies on daily basis."

"The course was very much insightful and fun. Knowledge was definitely impacted and I can say I've a broader understanding of Subsea systems engineering now."

Similar Courses