About the Course

The Subsea Pipelines course is an immersive training programme designed to provide subsea engineers with a foundational understanding of pipeline systems used in the offshore oil and gas industry. This course comprehensively covers the technical and practical aspects of subsea pipelines from conception through to decommissioning, offering delegates a broad perspective on the complexities involved in their design, installation, and maintenance.

At the heart of the course is the study of pipeline systems, focusing on the intricacies of field layouts and the use of pipelines and cables in subsea settings. Delegates will explore various subsea equipment and understand how platforms and floating production systems are integrated with pipeline infrastructure. The content further delves into riser configurations, providing insight into the engineering challenges and solutions associated with connecting subsea systems to surface facilities.

Route selection and the accompanying surveys are critical components of the course. Delegates will learn about the different types of surveys needed for effective route selection, including geophysical and hydrographic surveys, and the techniques employed to gather necessary data. This knowledge is crucial for ensuring the safe and efficient routing of pipelines along the seabed.

Another significant aspect of the course covers the manufacturing processes of pipes, including both rigid steel pipes and flexible pipes, and the selection of materials based on strength and corrosion resistance. The course details the differences between clad and lined pipelines, helping delegates make informed decisions regarding material and design to enhance the durability and functionality of subsea pipeline systems.

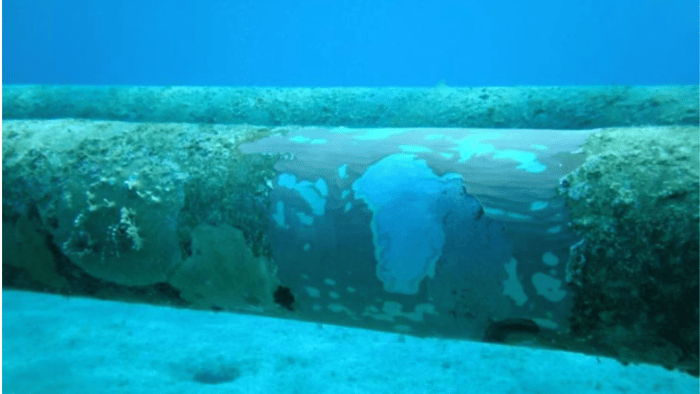

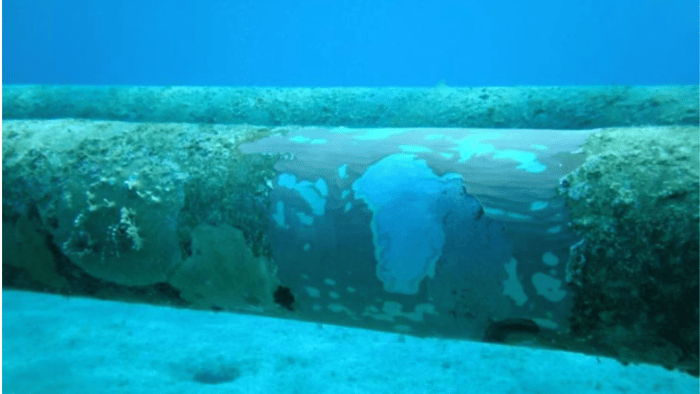

Pipeline design principles form a core module of the training, where delegates are taught to calculate pressures, size diameters, and determine wall thicknesses for various conditions such as bursting, hydrostatic collapse, and local buckling. Understanding global buckling, external coatings, and external corrosion and protection through methods like cathodic protection are also included to give a thorough grounding in the design and safeguarding of subsea pipelines.

Installation methods are a key focus, with detailed discussions on S-lay, J-lay, and Reel-lay techniques, alongside less conventional methods such as bundles and towed installations. The course also addresses the construction and pre-commissioning stages of pipeline projects, including welding, non-destructive testing (NDT), trenching, and burial.

Operationally, the course covers pipeline integrity and maintenance, including flow assurance, operational controls, and the use of additives and pigging to maintain pipeline efficiency and safety. Delegates will engage with real-world case studies to identify best practices and learn from past incidents, providing a practical perspective on managing pipeline systems.

In addition to technical skills, the course emphasises the importance of pipeline integrity management systems (PIMS) and risk-based inspection plans. It concludes with an exploration of pipeline decommissioning and the regulatory frameworks that govern subsea operations, ensuring delegates are well-versed in the lifecycle management of subsea pipelines.

Overall, this course is designed not just to impart technical knowledge, but to cultivate a comprehensive understanding of subsea pipeline engineering, preparing delegates to contribute effectively to the industry and advance their careers in subsea engineering. Through a blend of theoretical learning and practical application, the Subsea Pipelines course is an essential stepping stone for any subsea engineer looking to enhance their expertise in this critical field.

Who's it for

The Subsea Pipelines course is ideal for a range of professionals in the oil and gas industry who are involved in or wish to learn about subsea pipeline projects. It is particularly beneficial for:

-

Early-career Subsea Engineers seeking to build foundational knowledge in pipeline systems.

-

Project Managers who oversee the development and maintenance of subsea infrastructure.

-

Technical staff involved in the design, installation, and operation of subsea pipelines.

-

Safety and Compliance Officers focused on understanding the regulatory and environmental aspects of pipeline operations.

Learning Objectives

Upon completing the Subsea Pipelines course, delegates will be able to:-

Understand the principles of subsea pipeline design, including material selection and engineering considerations for functionality and durability.

-

Gain proficiency in various pipeline installation methods such as S-lay, J-lay, and Reel-lay, and understand their specific applications.

-

Develop strategies for effective pipeline integrity management, including inspection, maintenance, and repair protocols to ensure operational safety and compliance.

-

Acquire an understanding of the legal and environmental regulations that impact subsea pipeline operations.

-

Analyse real-world case studies to identify best practices and lessons learned in subsea pipeline projects.

Course Content

-

Day One

Introduction of pipeline systems

-

Example field layouts

-

Pipeline and cable uses

-

Subsea equipment

-

Platforms and floating production systems

-

Riser configurations

Route selection

-

Survey types

-

Survey techniques

-

Routing of pipelines

Pipe manufacture

-

Rigid steel pipe

-

Flexible pipe

Materials

-

Selection for strength

-

Selection for corrosion resistance

-

Clad and lined pipelines

-

-

Day Two

Pipeline design

-

Pressure

-

Design approaches

-

Diameter sizing

-

Wall thickness for bursting

-

Wall thickness for hydrostatic collapse

-

Wall thickness for local buckling

-

Global buckling

External coatings

-

External corrosion and protection

-

Cathodic protection

-

On-bottom stability

-

Thermal insulation and management

Common work

-

Construction survey

-

Route preparation

-

Welding

-

Non-destructive testing (NDT)

-

-

Day Three

Installation methods

-

S-lay

-

J-lay

-

Reel-lay

-

Bundles and towed installations

-

Flexibles and umbilicals

Construction support

-

Landfalls

-

Trenching and burial

-

Pre-commissioning

Tie-ins, spools and risers

-

Tie-ins and spools

-

Rigid steel riser installation

-

Flexible riser installation

Pipeline operations

-

Flow assurance

-

Operational controls

-

Additives

-

Pigging

-

Safety systems

-

-

Day Four

Introduction to pipeline integrity

-

Failures: frequency and incidents

-

PIMS

Pipeline inspection

-

Risk-based inspection plan

-

External survey

-

Internal inspection

-

Anomaly assessment

Repairs and modifications

-

Repairs

-

Hot taps, tees and wyes

-

Remedial works

Decommissioning

-

Regulations

-

Case studies

-

Learning Outcomes

Upon completion of this course, participants will be able to:

-

Explain key considerations for pipeline design

-

Compare appropriate manufacturing methods and material selection

-

Apply knowledge of installation processes and construction support to projects

-

Explain the principles of pipeline integrity, including flow assurance and inspection

-

Identify the importance of repairs and decommissioning

-

Explain regional differences

-

Class Materials

- Case studies that explore real-world subsea engineering challenges and their solutions.

- A comprehensive course manual detailing all essential topics and technical data.

- Detailed notes from the tutor, Phil Goby, offering additional insights and expertise.

- A collection of references and practical worked examples to deepen understanding and application of the material.

-

Jeenius

Participants in the Subsea Pipelines course gain access to Jeenius, a cutting-edge learning platform that offers comprehensive support tools. This platform includes all course notes, recordings of the sessions for later review, and the opportunity for one-on-one support with the tutor. Additionally, Jeenius provides access to the latest insights in subsea engineering, enhancing the learning experience with up-to-date industry knowledge.

-

In-Company Delivery

For in-company delivery options and content customisation to meet your specific needs, please don't hesitate to reach out to us.

Book one of our in-company courses, tailored to your team.

Your Tutors

Phil Goby

BEng (Hons), CEng, MIMechE

LEAD TUTOR

As the tutor for our Subsea Pipelines course, Phil leverages his extensive practical knowledge to provide students with a real-world perspective on subsea pipeline engineering challenges. He adeptly bridges the gap between theoretical concepts and their practical applications, ensuring that students gain a thorough and practical understanding of the subject matter.

Testimonials

"I appreciate the tutor support I have received; the explanation to my questions has helped me to solve my doubts. I am enjoying my Subsea pipelines course."

“Perfect introductory course for anyone looking to learn about subsea pipelines. The tutor kept it interesting and you can tell he is very experienced and passionate about the material taught. Better than can be found at most universities”

Similar Courses