This course, grounded in practical, real-world scenarios, provides insights into the latest industry standards and trends, ensuring the material is both theoretically sound and immensely practical. Additionally, you'll have the opportunity to connect with professionals and experts, enhancing your career development and industry engagement. Join us for a course that promises to equip you with the skills and knowledge to excel in the field of pipeline pigging.

Course Content

-

Day One

Introduction to pigging

-

Overview of pigs

-

Types of pigging programmes

Flow assurance

-

Introduction to flow assurance

-

Flow regime

-

Causes of flow restriction

-

Flow control methods

Piggability

-

Design of pigs

-

Pig design validation

-

Tracking design

Pig design

-

Design of pigs

-

Pig design validation

-

Tracking design

Launching and receiving

-

Pig trap design

-

Principles of pig launching and receiving

-

Main issues

-

Risk assessment procedures

-

Operational pigging

-

-

Day Two

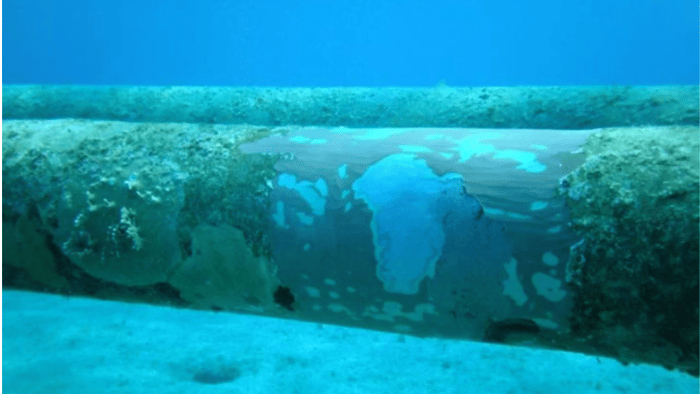

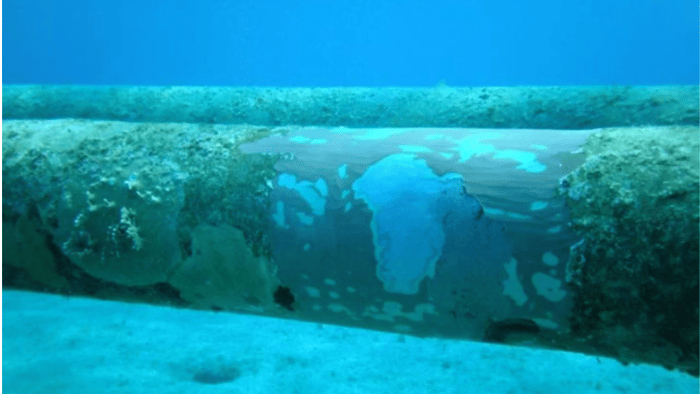

Pipeline cleaning

-

Pipeline cleaning strategy

-

Operational maintenance pigging

-

Pig types and function

Inspection tools

-

Gauge pig

-

Calliper pig

-

Magnetic flux pig

-

Ultrasonic pig

-

Inertial mapping unit

-

Inspection of flexibles

-

Other inspection technologies

-

Case study

Non-standard pigging operations

-

Requirements for non-standard pigging

-

Non-standard pigging/inspection technologies

-

Stuck/stalled pig contingencies

Pipeline isolation

-

High friction pigs

-

Types of plug

-

Plug design

-

Deployment

-

Setting/unsetting

-

Retrieval

-

Environmental issues

-

Learning Outcomes

Upon completion of this course, participants will be able to:

-

Explain the principles of operating pipeline pigs and isolation plugs

-

Compare different types of pigs and plugs and explain when and how they are used

-

Investigate problems that can occur when pigging and suggest resolutions

-

Apply industry lessons learned and best practice to your projects

-

Class Materials

- Case studies that explore real-world grid integration challenges and their solutions.

- A comprehensive course package detailing all essential topics and technical data.

- Detailed notes from the tutor, Phil, offering additional insights and expertise.

- A collection of references and practical worked examples to deepen understanding and application of the material.

-

Jeenius

Participants in the course gain access to Jeenius, a cutting-edge learning platform that offers comprehensive support tools. This platform includes all course notes, recordings of the sessions for later review, and the opportunity for one-on-one support with the tutor. Additionally, Jeenius provides access to the latest insights in renewable energy enhancing the learning experience with up-to-date industry knowledge.

-

In-Company Delivery

For in-company delivery options and content customisation to meet your specific needs, please don't hesitate to reach out to us.

-

Fee

£1,295 per person.

A discount is available if registering 3+ people.

Your Tutor

Phil Goby

BEng (Hons), CEng, MIMechE

LEAD TUTOR

As the tutor for our Integrity Management of Subsea Pipelines course, Phil leverages his extensive practical knowledge to provide students with a real-world perspective on subsea pipeline engineering challenges. He adeptly bridges the gap between theoretical concepts and their practical applications, ensuring that students gain a thorough and practical understanding of the subject matter.

Testimonials

"Jee delivers the promised topics. The course covered a lot of important topics and I feel more prepared to do my daily tasks at work. It gave me cohesion and the possibility to see the big picture."

“My basic understanding has increased significantly. I have enjoyed the course. Thank you.”

Similar Courses