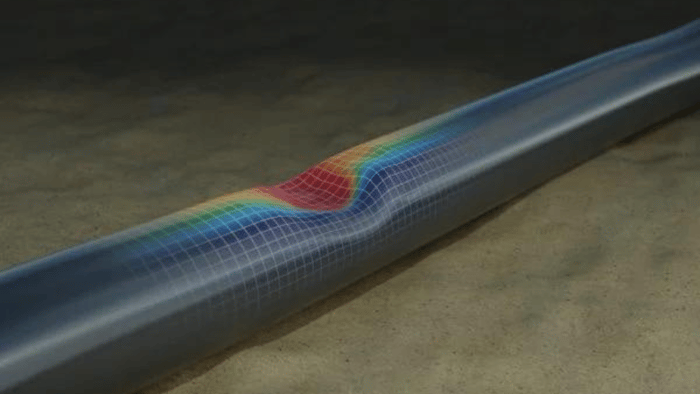

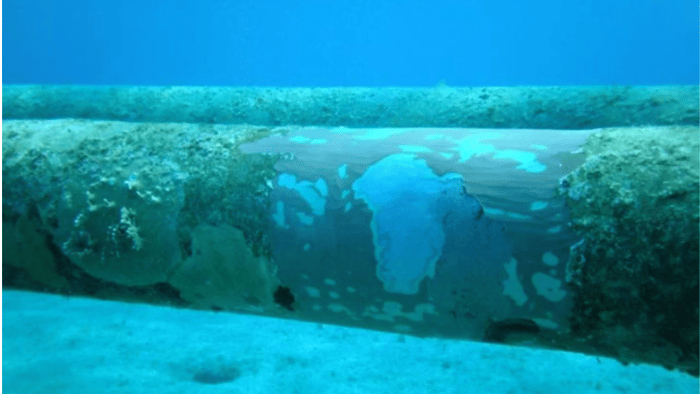

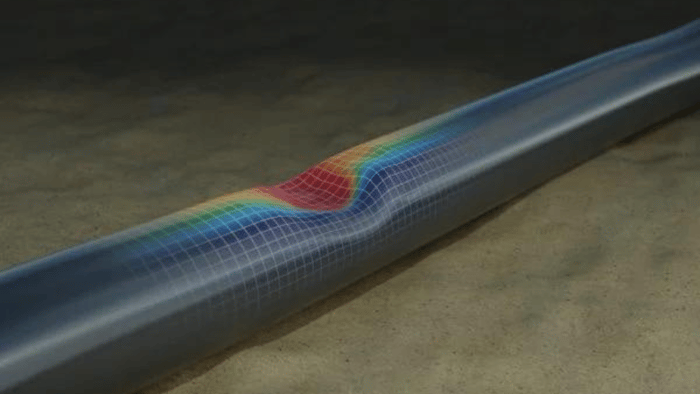

Master the art of corrosion management with this comprehensive course, Corrosion Defect Assessment. Through a combination of theoretical and practical exercises, you'll delve into the intricacies of corrosion threats, assess corrosion control measures, and master defect assessment strategies. You'll explore various corrosion types, categorise defects, and apply practical case studies to understand corrosion monitoring and inspection techniques.

Hands-on exercises will challenge you to apply your skills and knowledge to real-world scenarios, including determining the acceptability of a corrosion defect in a multi-phase pipeline system.

Course Content

-

Day One

Corrosion threats

-

Types of corrosion

-

Defect categorisation

-

Corrosion control measures and effectiveness

-

Corrosion monitoring and inspection techniques

-

Case studies

Fitness-for-service assessment

-

Classification of corrosion defects

-

Corrosion rate modelling

-

Corrosion defect interaction

-

Defect assessment approaches

-

Assessment limitations and applicability

-

Determination of fitness-for-service

-

Ongoing management

-

-

Day Two

ASME B31G approach

-

Differences between original and modified approach

-

Levels of assessment

-

Defect acceptance criteria and measurement uncertainty

-

Defect assessment worked example

-

Long defects and deep pits

DNVGL-RP-F101

-

Differences between Part A and Part B approach

-

Levels of assessment

-

Defect acceptance criteria and measurement uncertainty

-

Defect assessment worked example

-

Longitudinal and circumferential defects and validity limits

-

Supplementary use of Kastner approach

-

-

Day Three

Use of Finite Element Analysis (FEA)

-

When to move to an FEA based approach

-

Inspection data requirements

-

Application of API579

-

Corrosion defect modelling and determination of acceptability

-

Case study

ECA

-

Defects requiring ECA

-

Applicable codes and standards

-

DNVGL-RP-F108 and BS7910 approaches

-

Worked example

Exercise

-

Determine the acceptability of a corrosion defect identified by recent ILI run in a multi-phase pipeline system.

-

Learning Outcomes

Upon completion of this course, participants will be able to:

-

Understand and categorise different types of corrosion threats and their control measures.

-

Apply corrosion monitoring and inspection techniques effectively.

-

Conduct fitness-for-service assessments, understanding the role and limitations of different approaches.

-

Use corrosion rate modelling for defect assessment and ongoing management.

-

Understand and apply the ASME B31G and DNVGL-RP-F101 methodologies for defect assessment, identifying key differences and applicability between the original, modified, Part A, and Part B approaches.

-

Handle scenarios involving long defects, deep pits, and both longitudinal and circumferential defects.

-

Apply Finite Element Analysis (FEA) in the context of corrosion defect modelling and determination of acceptability, understanding when to shift to an FEA-based approach.

-

Conduct Engineering Critical Assessments (ECA) of defects, applying relevant codes and standards like DNVGL-RP-F108 and BS7910.

-

Determine the acceptability of a corrosion defect identified in a multi-phase pipeline system.

-

Utilise practical examples and case studies to apply theoretical knowledge to real-world scenarios.

-

Develop an appreciation for the complexity of corrosion management and defect assessment, and the importance of these skills in maintaining the safety and longevity of critical structures.

-

Class Materials

- Case studies that explore real-world grid integration challenges and their solutions.

- A comprehensive course package detailing all essential topics and technical data.

- Detailed notes from the tutor, Richard, offering additional insights and expertise.

- A collection of references and practical worked examples to deepen understanding and application of the material.

-

Jeenius

Participants in the course gain access to Jeenius, a cutting-edge learning platform that offers comprehensive support tools. This platform includes all course notes, recordings of the sessions for later review, and the opportunity for one-on-one support with the tutor. Additionally, Jeenius provides access to the latest insights in renewable energy enhancing the learning experience with up-to-date industry knowledge.

-

In-Company Delivery

For in-company delivery options and content customisation to meet your specific needs, please don't hesitate to reach out to us.

-

Fee

£2,495 per person.

A discount is available if registering 3+ people.

Your Tutor

Richard Espiner

MIMechE, MEng

LEAD TUTOR

Testimonials

"A recommended course for Engineer who wants to be the best in the Pipeline integrity management."

"It was an excellent training. I like how the materials contained simple steps to conduct FFS. The trainer demonstrated good experience and mastery."