Corrosion Defect Assessment

Navigating Corrosion Challenges: Delving into Defect Assessment Strategies

Interactive Learning

Industry insights

Networking Opportunities

Networking opportunities

Network with like-minded individuals and industry experts working within subsea corrosion.

Jeenius

Mastering Corrosion Management Through Practical Exercises

Module Highlights

Day 1 - Exploration of Corrosion Management - Types, Control Measures, and Fitness-for-Service Assessment

Day 2 – Mastery of Industry Standards - ASME B31G and DNVGL-RP-F101 Approaches

Day 3 –Advanced Pipeline Integrity Assessment: FEA and ECA Techniques

Who should attend?

Navigating the Course: Daily Breakdown

Corrosion threats

-

Types of corrosion

-

Defect categorisation

-

Corrosion control measures and effectiveness

-

Corrosion monitoring and inspection techniques

-

Case studies

Fitness-for-service assessment

-

Classification of corrosion defects

-

Corrosion rate modelling

-

Corrosion defect interaction

-

Defect assessment approaches

-

Assessment limitations and applicability

-

Determination of fitness-for-service

-

Ongoing management

ASME B31G approach

-

Differences between original and modified approach

-

Levels of assessment

-

Defect acceptance criteria and measurement uncertainty

-

Defect assessment worked example

-

Long defects and deep pits

DNVGL-RP-F101

-

Differences between Part A and Part B approach

-

Levels of assessment

-

Defect acceptance criteria and measurement uncertainty

-

Defect assessment worked example

-

Longitudinal and circumferential defects and validity limits

-

Supplementary use of Kastner approach

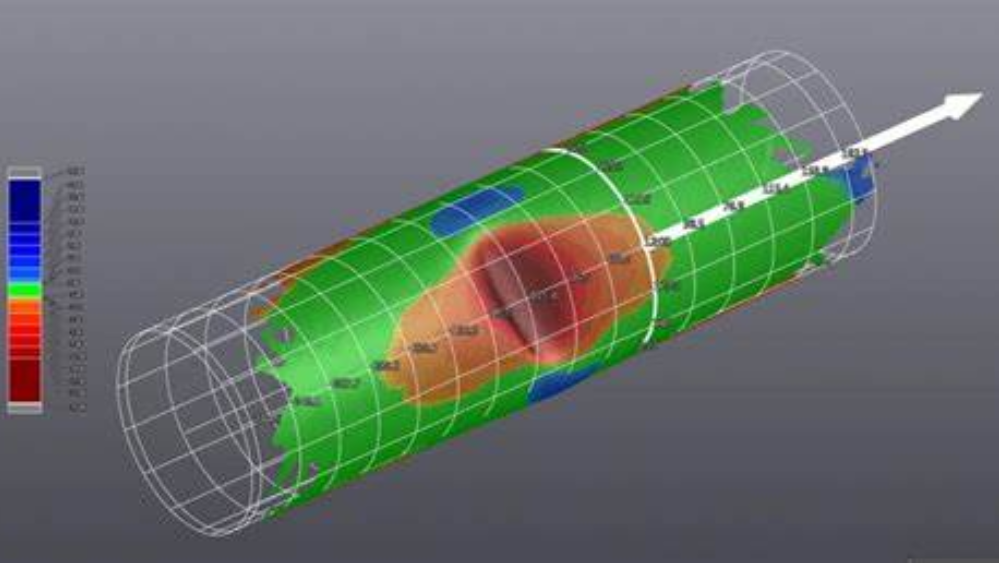

Use of Finite Element Analysis (FEA)

-

When to move to an FEA based approach

-

Inspection data requirements

-

Application of API579

- Corrosion defect modelling and determination of acceptability

-

Case study

ECA

-

Defects requiring ECA

-

Applicable codes and standards

-

DNVGL-RP-F108 and BS7910 approaches

-

Worked example

Exercise

-

Determine the acceptability of a corrosion defect identified by recent ILI run in a multi-phase pipeline system.

Learning Outcomes

- Understand and categorise different types of corrosion threats and their control measures.

- Apply corrosion monitoring and inspection techniques effectively.

- Conduct fitness-for-service assessments, understanding the role and limitations of different approaches.

- Use corrosion rate modelling for defect assessment and ongoing management.

- Understand and apply the ASME B31G and DNVGL-RP-F101 methodologies for defect assessment, identifying key differences and applicability between the original, modified, Part A, and Part B approaches.

- Handle scenarios involving long defects, deep pits, and both longitudinal and circumferential defects.

- Apply Finite Element Analysis (FEA) in the context of corrosion defect modelling and determination of acceptability, understanding when to shift to an FEA-based approach.

- Conduct Engineering Critical Assessments (ECA) of defects, applying relevant codes and standards like DNVGL-RP-F108 and BS7910.

- Determine the acceptability of a corrosion defect identified in a multi-phase pipeline system.

- Utilise practical examples and case studies to apply theoretical knowledge to real-world scenarios.

- Develop an appreciation for the complexity of corrosion management and defect assessment, and the importance of these skills in maintaining the safety and longevity of critical structures.

Meet Your Expert Tutors

Graham Wilson

MEng (Hons), CEng, MIMechE

Graham, serving as Jee's Head of Integrity Management, has over 20 years of industry experience. His credentials are further enhanced by his role as a Chartered Mechanical Engineer and a Fellow, showcasing his profound expertise and commitment to the engineering field. Graham's specialisations in integrity management, design, fishing interaction studies, and verification have positioned him at the forefront of the industry. Additionally, his significant contribution as the Convenor of ISO WG 17 illustrates his pivotal role in shaping international standards, further testament to his global influence and technical acumen.

In his capacity as Head of Late Life, Graham brings a strategic and comprehensive approach to managing the challenges of aging infrastructure and decommissioning processes. This role complements his extensive teaching responsibilities, where he leads courses in integrity management, corrosion defect assessment, and decommissioning programme development and execution. His ability to integrate real-world scenarios with theoretical knowledge offers a dynamic and immersive learning experience. Graham's teaching not only covers the essential principles but also delves into the complexities of managing the lifecycle of engineering projects.

Richard Espiner

Meng, CEng, MIMechE

Richard, a Chartered Mechanical Engineer, brings over 25 years of rich experience in various pipeline engineering roles, serving both consulting and operating companies. His specialisation lies in the crucial areas of pipeline integrity management, risk and reliability assessment, defect assessment, and in-line inspection. This extensive experience has equipped him with a deep understanding of the technical nuances and complexities inherent in pipeline engineering, making him a trusted expert in his field. Richard's proficiency in these areas is not just theoretical but is grounded in a wealth of practical, hands-on experience.

In his role as a Jee trainer, Richard stands out for his enthusiasm in interacting with a wide range of course delegates. He finds great satisfaction in sharing his wealth of experiences and insights, enriching the learning journey of his students. Additionally, Richard values the opportunity to learn from the diverse perspectives and experiences of the delegates, believing that education is a two-way process. His approach to teaching is characterised by a keen emphasis on practical application, ensuring that students not only grasp the theoretical concepts but also understand their real-world implications. Richard’s teaching style fosters an engaging and dynamic learning environment, encouraging active participation and the sharing of ideas. This approach not only imparts crucial technical knowledge but also prepares students for the collaborative and ever-evolving nature of the engineering industry.

Start Dates

| Location | Start Date | End Date | Number of Days | Timings |

|---|---|---|---|---|

Virtual (Live Instruction) |

14th May 2024 |

16th May 2024 |

4 |

09:00 to 16:30 (with regular breaks) |

Your Pricing Path: Course or Course Bundle

Standard Access

Individual Course Access

£2,495

-

Live Classes: Dive into live, interactive sessions focusing on real-time learning and discussions with peers and industry experts.

-

Access to Jeenius Platform: Unlock a realm of additional resources, peer forums, and expert interactions extending your learning beyond the classroom.

-

Industry Expert Interaction: Network and learn from seasoned industry professionals throughout the course, discussing real-world challenges and solutions.

Premium Access

Integrity Management Bundle

Unlimited lifetime access to all of our Integrity programmes.

£9,995

For just £9,995, you'll unlock lifetime access to our full spectrum of integrity courses, a collection with a value exceeding £30,000.

This offer isn't just about diverse subjects like Integrity Management, Lessons Learned, Flexibles and Riser, and more; it's a gateway to limitless learning.

Enjoy the freedom to access all materials and attend live classes whenever you wish, from anywhere, at any time. Elevate your expertise on your terms and at your convenience, ensuring a dynamic and flexible educational journey

Find Out more